E-House

The E-House Journey: From Manufacturing to On-Site Testing and Commissioning

Kontrolmatik delivers turnkey E-House solutions from its Mobile Energy Solutions Factory in Ankara, covering engineering, E-House manufacturing, equipment procurement, system integration, Factory Acceptance Tests (FAT), Site Acceptance Tests (SAT), and commissioning.

Projects are executed through an end-to-end integrated approach, fully aligned with international standards and customer requirements. E-House systems are meticulously controlled at every stage—from manufacturing to on-site testing and commissioning ensuring high quality, operational reliability, and uninterrupted power continuity.

Kontrolmatik’s turnkey E-House solutions provide fast installation, safe operation, and long-term performance for power distribution, oil & gas, renewable energy, industrial facilities, and infrastructure projects.

What is E-House?

An E-House (Electrical House) is a prefabricated or modular substation structure specifically designed to house electrical equipment and systems. Serving as a centralized solution for power distribution, control, and automation equipment, E-House structures provide a secure, protected, and climate-controlled environment for critical electrical components.

E-House systems consist of pre-assembled, factory-tested, and project-specific power systems. This approach significantly reduces on-site installation time, accelerates commissioning processes, and minimizes operational risks.

Thanks to their flexible designs, prefabricated E-House substations deliver fast, reliable, and sustainable energy solutions across a wide range of sectors, including power distribution, oil & gas, renewable energy, industrial facilities, and infrastructure projects. They also offer an ideal solution for emergency situations and temporary power requirements.

Equipped with integrated power systems, SCADA, and building automation capabilities, E-House solutions consolidate diverse electrical needs into a compact, scalable, and turnkey system.

Kontrolmatik E-House Everywhere: Asia, Europe, Africa, the Middle East, and the Americas

Turnkey E-House solutions manufactured by Kontrolmatik are fully compliant with all ISO certifications and also incorporate region-specific certifications in line with the geographical and regulatory requirements of each project. These prefabricated or fixed electrical rooms (E-House) are created by integrating all electrical, control, and automation systems required in a distribution facility into containerized or prefabricated structures.

All certified equipment used in E-House systems is assembled, commissioned, and fully tested at the factory prior to site delivery. This approach minimizes on-site risks while significantly reducing installation and commissioning timeframes.

E-House solutions offer pre-commissioned, plug-and-play systems for temporary, emergency, or permanent power distribution applications. Once delivered to site, the systems can be rapidly commissioned with only cable connections, providing substantial time and cost savings during both initial investment and ongoing operations.

Turnkey E-House Solutions from Manufacturing to On-Site Testing and Commissioning

Kontrolmatik delivers turnkey Prefabricated and Containerized E-House solutions from its Mobile Energy Solutions Factory in Ankara, covering engineering and design, E-House system manufacturing, equipment procurement, system integration, Factory Acceptance Tests (FAT), Site Acceptance Tests (SAT), and commissioning.

Projects are executed through a fully end-to-end integrated approach, in strict compliance with international standards and customer-specific requirements. All systems are assembled, tested, and pre-commissioned at the factory prior to shipment, significantly reducing on-site installation time, minimizing operational risks, and ensuring safe and timely commissioning.

Kontrolmatik’s turnkey E-House solutions offer fast deployment, high operational reliability, and long-term performance for power distribution, oil & gas, renewable energy, industrial facilities, and infrastructure projects.

Advantages of E-House

Factory-tested prefabricated E-House solutions offer significant operational and economic advantages for the process industry, mining, oil & gas, power plants, urban infrastructure, and many other application areas. Compared to conventional solutions, turnkey E-House systems provide a faster, more reliable, and more flexible alternative.

Key Advantages of E-House Systems

-Completed in a significantly shorter time compared to conventional solutions

-Engineering and detailed design phases are substantially reduced

-Plug-and-play configuration minimizes on-site installation time

-Requires less space compared to traditional building solutions

-Can be designed in compliance with ISO standards or project-specific dimensions

-Site conditions do not affect manufacturing and delivery schedules

-Can be relocated and reinstalled after the end of the facility’s service life

-Optimized equipment integration reduces cable lengths and overall cabling costs

-Factory Acceptance Tests (FAT) completed prior to delivery shorten testing and commissioning time

Thanks to these advantages, prefabricated E-House solutions enable time savings, lower capital investment costs, and high operational reliability across projects.

Flexible and Tailor-made Mobile Substation Solutions

Advanced E-House Engineering Studies

Developing suitable solutions in E-House product requires experience. As Kontrolmatik, we make all electrical, static and mechanical designs of E-House products with our strong engineering staff. Some of the standards that our company, which produces and designs in accordance with Europe, America, Turkey and many other standards, works are as follows; ANSI/ASME/AISC/NEMA/ASTM/AWS, TSE, SI, EUROCODE/IEC/EN/BS.

E-House Production from A to Z with a Strong Production Staff

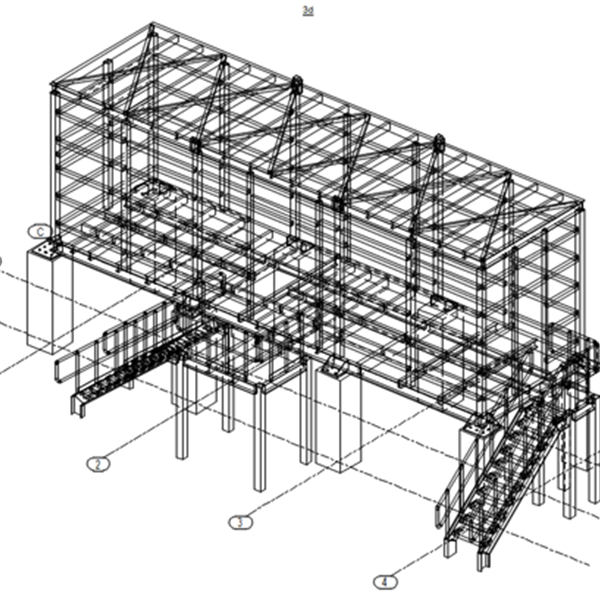

Kontrolmatik carries out all E-House manufacturing within its body and exports it to 32 countries with its mobile energy solutions factory in Ankara, Turkey with an area of 8.000 m2. The E-House, whose design is completed according to the region and need in which they will be used, pass to the production stage. Base, steel skeleton, interior-exterior wall panels, roof etc. prefabricated structure is revealed. Parallel to this, the production of the electrical equipment, which is planned to be located, continues and the mechanical assembly is completed.After the factory test and commissioning works are completed, it is ready for transport to the region where it will be used.

E-House Usage Areas

Our E-House products, which serve as plug-and-play in prefabricated / container types, operate smoothly in harsh conditions between -40 and +50 degrees. Our E-House (electric room) products, which are used in many different areas, are generally preferred in the following situations:

-When an emergency power supply is required,

-Spare unit in case of natural disasters,

- When continuity of service is required for planned construction, maintenance and inspection programs,

-In excess of capacity needs,

-In new facility installations.

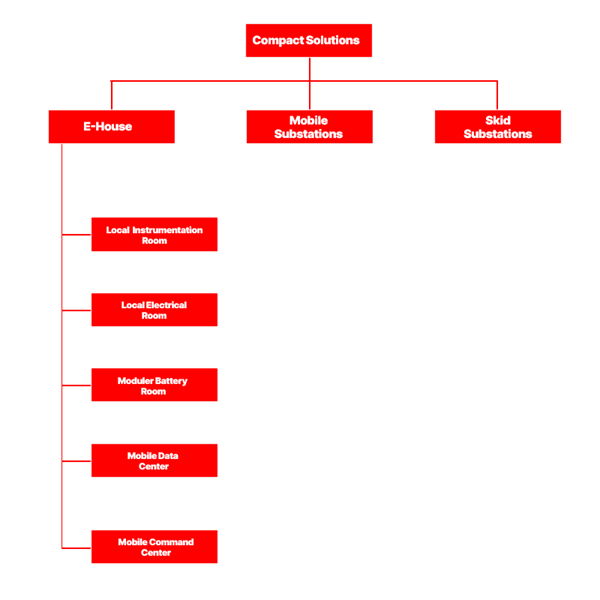

Compact Solutions

Kontrolmatik produces turnkey compact solutions from engineering, production, equipment supply, assembly and integration to factory and field testing and commissioning at the Mobile Solutions Factory in Ankara.

What is the E-House?

1.Purpose: The primary purpose of an Engineering House is to centralize and protect critical electrical and instrumentation equipment in an industrial facility. This can include switchgear, motor control centers, transformers, control systems, and other essential components.

2.Prefab Construction: E-Houses are typically constructed off-site as modular units. This allows for standardized designs and efficient assembly, reducing on-site construction time and costs.

3.Electrical Distribution: E-Houses house electrical distribution equipment, including circuit breakers, transformers, and switchgear. This centralized location facilitates the efficient distribution of electrical power to various parts of the industrial facility.

4.Instrumentation and Control Systems: In addition to electrical components, E-Houses often accommodate instrumentation and control systems. This includes control panels, distributed control systems (DCS), and other monitoring and automation equipment necessary for the operation of the facility.

5.HVAC Systems: To ensure the proper functioning of sensitive electronic equipment, E-Houses are equipped with heating, ventilation, and air conditioning (HVAC) systems. These systems help regulate temperature and humidity levels inside the house.

6.Fire Suppression and Safety Features: Given the critical nature of the equipment housed within, E-Houses are equipped with fire suppression systems and other safety features to protect against potential hazards.

7.Modularity and Scalability: E-Houses are designed to be modular and scalable. As industrial facilities expand or equipment requirements change, additional E-Houses can be added or modified to accommodate the evolving needs of the facility.

8.Transportability: E-Houses are often designed for ease of transportation. They can be transported to the construction site and easily integrated into the overall facility infrastructure.

By consolidating critical electrical and instrumentation equipment in a dedicated structure, E-Houses contribute to the efficiency, safety, and reliability of industrial operations. Their modular design and prefabrication make them a practical solution for various engineering and construction projects.

Industries For E-House Applications

1. Power Generation:

- E-Houses are frequently used in power plants, including coal, gas, nuclear, and renewable energy facilities.

- They house essential electrical distribution and control equipment for power generation and transmission.

2. Oil and Gas:

- E-Houses are deployed in upstream, midstream, and downstream oil and gas facilities.

- They house equipment for power distribution, control systems, and instrumentation critical to the extraction, processing, and transportation of oil and gas.

3. Mining:

- In mining operations, E-Houses serve as centralized hubs for electrical and control equipment, supporting various mining processes and machinery.

4. Chemical and Petrochemical:

- Chemical and petrochemical plants utilize E-Houses to house electrical and control systems for the processing and manufacturing of chemicals and petrochemical products.

5. Water and Wastewater Treatment:

- E-Houses are employed in water treatment and wastewater treatment facilities to house electrical and control equipment essential for water purification and treatment processes.

6. Manufacturing:

- Industries such as automotive, steel, and other manufacturing sectors use E-Houses to centralize electrical distribution and control systems for their production facilities.

7. Renewable Energy:

- E-Houses are utilized in renewable energy projects, including solar and wind farms, to house electrical equipment related to power generation and distribution.

8. Data Centers:

- E-Houses can be used in data centers to house electrical distribution systems, backup power systems, and control equipment for efficient and reliable data center operations.

9. Transportation Infrastructure:

- E-Houses are used in transportation sectors like railways and airports to house electrical and control systems for signaling, lighting, and other critical infrastructure.

10. Telecommunications:

- In the telecommunications industry, E-Houses can be used to house equipment related to power distribution, backup power systems, and control systems for communication networks.

11. Pharmaceutical and Biotechnology:

- E-Houses find applications in pharmaceutical and biotech facilities to house electrical and control systems supporting the production of pharmaceutical products.

These are just a few examples, and the use of E-Houses can extend to various other industries where centralized housing of electrical and instrumentation equipment is necessary for efficient and safe operations. The modular and scalablenature of E-Houses makes them adaptable to the specific needs of different industries and projects.

Why Kontrolmatik?

1. Customization and Flexibility:

- Kontrolmatik offers customization options to meet the specific needs of our clients. The ability to tailor E-Houses to unique project requirements set our company apart.

2. Innovative Technology Integration:

- Kontrolmatik stay at the forefront of technological advancements in E-House design. We Integrate the latest smart technologies, energy-efficient solutions, and advanced control systems to provide cutting-edge solutions to our clients.

3. Modular Design and Scalability:

- We emphasize the modular design of our E-Houses, highlighting the ease of scalability. This flexibility allows for quick adaptation to changing project requirements and expansion plans.

4. Quality and Reliability:

- We ensure high quality construction and reliability in our E-Houses. We ensure the longevity and performance of our product through rigorous testing, compliance with industry standards and the use of durable materials.

5. Efficient Project Management:

- Thanks to our project management processes to deliver E-Houses on time and within budget. Reliable project timelines and efficient execution are significant competitive advantage of Kontrolmatik.

6. Cost-Effective Solutions:

- Kontrolmatik offers cost-effective solutions without compromising quality. It provides competitive pricing through efficient production processes, economies of scale and strategic sourcing.

7. Environmental Sustainability:

- Kontrolmatik incorporate energy efficient components and sustainable practices into our E-Houses. We would like to emphasize that we are aware of our environmental responsibilities for a greener future.

8. Global Presence and Support:

- We form strategic partnerships with other industry leaders, suppliers or technology providers to enhance our company's capabilities and deliver comprehensive solutions.

9. Customer Support and Training:

- We offer excellent customer support, including training programs to help our customers effectively operate and maintain E-Houses. We always support our customers by building long-term relationships through ongoing support.

10. Industry Certifications and Compliance:

- We confirm relevant industry certifications and compliance with international standards. This is our commitment to safety and quality standards ensuring high quality and standardization.

11. Collaborative Partnerships:

- We form strategic partnerships with other industry leaders, suppliers or technology providers to enhance our company's capabilities and deliver comprehensive solutions.