The full scope of EPC, including all conceptual and detailed engineering work, supply of main and auxiliary equipment, construction, installation and commissioning, has been undertaken. Approximately 800 personnel were deployed on site during the peak period of the project. The facility was completed on time and successfully.

Kontrolmatik proudly delivered the Van Solar Power Plant as a turnkey renewable energy project.

This significant facility meets 20% of the total electricity demand with solar energy, generates 18 million kWh of clean energy annually, and prevents approximately 15,000 tons of carbon emissions per year.

By managing the entire process from engineering and procurement to construction, installation, and commissioning Kontrolmatik delivers end-to-end turnkey solutions that support the global transition to sustainable energy.

It is Türkiye’s first floating solar power plant project. A 1 MWp solar power plant was successfully delivered on a turnkey basis, including engineering, procurement, and installation (EPC) services.

Within the scope of the Energy Efficiency in Public Buildings Project (KABEV), we increased the use of renewable energy by installing Solar Energy Systems with a total capacity of 2.8 MWp on rooftops and parking areas.

The existing conventional boilers were replaced with a cascade system consisting of seven condensing sectional boilers, each with a capacity of 4,126 kW, significantly improving heating efficiency.

As part of the lighting retrofit, 21,231 inefficient luminaires were replaced with LED technology, resulting in reduced energy consumption.

To prevent excessive heat gain on building façades, fixed horizontal louver sun-shading systems and UV-protective film applications were implemented, achieving both energy savings and improved indoor comfort.

Within the scope of the construction of a new terminal to support the existing terminal, the installation and commissioning of the SCADA Energy monitoring system in this new terminal and the configuration of the Network system, communication and RTUs were carried out.

Kontrolmatik contributed to doubling production capacity in the Ratawi Oil Field project with its turnkey modular E-House solution.

Turnkey Reducing Mobile Substation with 33kV/11kV voltage and 31.5MVA power

Complete electrification of 50MW Dual fuel (Gas/HFO) power plant in Walvis Bay Namibia within the EBoP (Electrical Balance of Plant) Package.

Kontrolmatik provided comprehensive engineering and field solutions to ensure the safe and uninterrupted operation of the wind energy infrastructure at the Balabanlı WPP 33/154 kV Substation Project.

In Basra, Iraq, as part of the strengthening of the power transmission and distribution infrastructure, one (1) set of 132/33 kV, 31.5 MVA High Voltage Mobile Substation was designed, supplied, installed, and commissioned on a turnkey basis by Kontrolmatik.

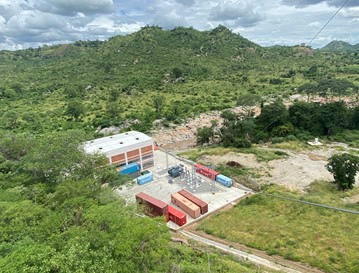

Kontrolmatik has successfully completed the design, manufacturing, and supply of the LCI E-House within the scope of the Singrobo Hydroelectric Power Plant project located in Côte d’Ivoire.

As part of the project, an integrated, factory-tested LCI E-House solution compliant with international standards was delivered to ensure the safe, efficient, and uninterrupted operation of the hydroelectric power plant. The system was engineered specifically for the project and manufactured by taking site conditions into full consideration.

Within this scope:

-

Detailed engineering and design studies were carried out for the LCI E-House,

-

Prefabricated E-House manufacturing and system integration were completed,

-

All systems were verified through Factory Acceptance Tests (FAT),

-

Transportation and delivery of the E-House to site were successfully completed.

Within the scope of the Uşak RES 154 kV Feeder Extension project, Kontrolmatik carried out the addition of one transformer feeder, the addition of two line feeders, and the revision of one transformer feeder. The project also included all civil works within the switchyard, installation and erection of primary and secondary equipment, as well as grid connection and synchronization. As a result, the facility was successfully integrated into the grid in a safe, reliable, and standards-compliant manner.

Within the scope of the 110 kV Power Transmission Line and Substation project, Kontrolmatik delivered the turnkey construction of a 20/90 kV step-up substation with a capacity of 2×24 MVA, along with a 14 km overhead transmission line. The project covered all engineering, supply, construction, installation, testing, and commissioning activities, ensuring reliable and secure power transmission in full compliance with applicable standards.

Complete Rehabilitation and Electrification with Complete Engineering, Design, Procurement, Supply, Installation and Testing and Commissioning of High Voltage, Medium Voltage, Low Voltage Systems, Substation Transformer, Switchgears, UPS Systems, SCADA Systems and Telecommunication Systems for Kenya Gitaru Hydroelectric Power Plant.

EPC High Voltage Substation

Installation of 500 kW/500 kWh Battery Electricity Storage Systems Including Installation and Network Connections to MEDAŞ General Directorate.

MCC-ECS Environmental Control System

Within the scope of the project implemented to strengthen the electricity transmission and distribution infrastructure in the Duhok region of Northern Iraq, a total of six Mobile Substation Systems (MSS) comprising 3 × 132/33 kV, 25 MVA and 3 × 33/11 kV, 31.5 MVA units have been delivered on a turnkey basis.

Engineering, Design and Manufacturing

Engineering, Design, Supply, Installation and Testing and Commissioning of Medium Voltage Switchgears, Low Voltage Switchboards, High Voltage Power Transformers, SCADA Control System, DC Switchboards and DC System and UPS System

Within the scope of the KfW Lot-1 Mosul Substations project, Kontrolmatik delivered the turnkey engineering, design, manufacturing, supply, installation, testing, and commissioning of three air-insulated substations (AIS) and one gas-insulated substation (GIS) at the 132/33 kV voltage level in Mosul, Iraq, financed under the KfW fund. The project significantly strengthened the region’s power transmission infrastructure, ensuring safe, reliable, and sustainable electricity supply.

Within the scope of the Tedzani IV HPP project, Kontrolmatik delivered the Electrical Balance of Plant (EBoP) package for the Tedzani IV Hydropower Plant in Malawi, covering the complete electrification of the plant. The scope of work included the engineering, supply, installation, testing, and commissioning of the high-voltage substation and the high-voltage transmission line. As a result, the plant was equipped with a safe, efficient, and internationally compliant electrical infrastructure.

Üsküdar–Çekmeköy Metro Line project, Kontrolmatik delivered the Tunnel Ventilation Control System and Central Control Room solutions for tunnels and stations. Within the scope of the project, automation infrastructure, monitoring and control scenarios, and central SCADA integration of the ventilation systems were implemented. The deployed solution ensures operational continuity, passenger safety, and effective emergency management through a fully integrated and reliable control system.

EPC 400 kV GIS Substation

Within the scope of the Nuri Şeker Uşak Sugar Factory project, Kontrolmatik delivered the engineering, installation, and commissioning of the synchronization, load taking–load shedding automation, protection and alarm systems, and the SCADA system for the Steam Turbine – Turbo Generator Group. Through this project, safe, reliable, and efficient operation of the power generation processes was ensured, and the plant operations were equipped with a centralized and fully integrated control infrastructure.

EPC High Voltage Substation

IEC 61850, SCADA, RTU, Communication System and Panel Supply, Commissioning and Supervision Works

Engineering, Design, Manufacturing, Supply, Installation, Testing and Commissioning of MCC and PLC Panels, Instrumentation and Piping, Civil Works and Civil Engineering, CCTV and Security Systems, Process Equipment and Central Control Room Automation, Modernisation and Rehabilitation works at ISKI Kağıthane Water Treatment Plant.

Turnkey Substation construction at 110kV Voltage including Engineering, Design, Fabrication, Procurement, Supply, Installation and Testing and Commissioning for 470MW Combined Cycle Natural Gas Power Plant and Overhead transmission line in Tashkent, Uzbekistan.

By Kontrolmatik, the rehabilitation works for two 2720 kVA generators have been successfully completed, including the renewal of excitation systems, modernization of synchronization systems, upgrade of generator protection systems, and replacement of generator output circuit breakers.

Within the scope of the project, the installation of a SCADA system for energy monitoring and control for both generators was also completed, along with the supply and commissioning of battery/charger (rectifier) and power supply systems. All engineering, procurement, on-site installation, system integration, testing, and commissioning activities were carried out in compliance with international standards.

As a result of the modernization works, the operational reliability, synchronous operation capability, and system monitoring and traceability of the generator systems have been significantly enhanced.

Panel Manufacturing, SCADA and Secondary Systems Installation.

Within the scope of the Cenergo CCPP 220 kV Substation and Underground Cable Line project, Kontrolmatik delivered the turnkey engineering, design, manufacturing, supply, installation, testing, and commissioning of a 220 kV substation for a 240 MW Combined Cycle Natural Gas Power Plant located in Uzbekistan. The project ensured a safe, reliable, and continuous grid connection of the power plant through a high-voltage infrastructure implemented in compliance with international standards.

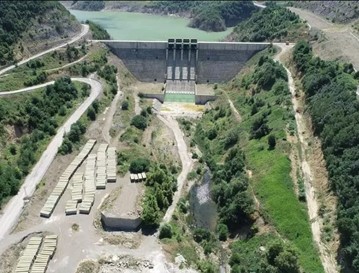

Within the scope of the Kirazlık Hydroelectric Power Plant Automation and Electrification Systems project, Kontrolmatik delivered the engineering, design, supply/manufacturing, installation, testing, and commissioning of the generator and transformer protection systems, low-voltage switchboards, MCC panels, synchronization system, battery–UPS system, and the SCADA system. The integrated automation and electrification solutions ensured safe, reliable, and high-efficiency operation of the power plant.

110/20kV Turnkey Step Up Substation including Engineering, Design, Fabrication, Supply, Installation and Testing and Commissioning for Solar Power Plant in Oslomej, North Macedonia

Installation of Electrical Systems and Automation System of Dehydrated Borax II Plant in Eti Maden Kırka Facilities.

Complete electrification of Faizabad Hydro Power Plant in Afghanistan within the scope of EBoP (Electrical Balance of Plant) Package.

Tunnel Ventilation Control System

Within the scope of the Yarımca Port RTU and SCADA System project, Kontrolmatik delivered IEC 61850–based SCADA and RTU systems, including the supply of communication systems and control panels, as well as commissioning and control activities. The implemented solution enabled reliable real-time monitoring, control, and secure operation of the port’s electrical infrastructure through an integrated and standards-compliant automation system.

Turnkey EPC contract including Design, Engineering, Procurement, Supply, Installation Testing and Commissioning of 154/31.5kV Downstream Substation for the connection of a poultry factory to the electricity grid in Adana, Turkey.

Turnkey Reducing Mobile Substation with 33kV/11kV voltage and 16MVA power for Distribution Reinforcement in Electricity Grid

Within the scope of the North Marmara Natural Gas Storage Expansion Project, Kontrolmatik delivered the engineering, construction, installation, testing, pre-commissioning, and commissioning of the electrical, instrumentation, and control (EIC) systems covering the onshore facilities, New Surface Facility (NSP), North Marmara Gas Field (NMGS), offshore platforms, and the BOTAŞ connection. The project significantly enhanced the operational capacity, safety, and reliability of the natural gas storage facility in full compliance with international standards.

Combined Cycle Natural Gas Power Plant in Khorazm, Uzbekistan Complete electrification of the plant, 220kV High Voltage Substation and Transmission Line within the EBoP (Electrical Balance of Plant) Package.

Construction of a Turnkey Substation with a capacity of 2x50MVA at 132/33kV Voltage including Engineering, Design, Manufacturing, Procurement, Installation and Testing and Commissioning within the scope of grid connection of a steel production facility in Kalar, Northern Iraq.

IEC 61850, HEPP 154kV Substation, Control System, Secondary and Communication System, Supply and Supervision works.

Within the scope of the Enerjisa Erciyes WPP project, Kontrolmatik delivered the engineering, supply, installation, and commissioning of the 154 kV substation, fiber optic (FO) cable system, grounding conductors, as well as the 34.5 kV electrical, communication, control, and grounding systems. The project ensured safe, reliable, and standards-compliant grid integration of the wind power plant.

Within the scope of the Garoua–Maroua Substations project, Kontrolmatik delivered the design, supply, and installation of high-voltage substations. The project contributed to strengthening the regional power transmission infrastructure by ensuring reliable, safe, and standards-compliant electricity distribution.